Quantify your containers’ experience on the production line.

Experience your line from the inside — SmartSkin reveals what your containers feel, so you can optimize every run.

Industries served

Purpose-built solutions to help you protect your products.

DIAGNOSE. ANALYZE. OPTIMIZE.

Data-driven analysis of forces impacting your products.

SmartSkin’s solutions combine innovative digital container twins and proprietary software to provide manufacturers with actionable data that helps them improve productivity, saving them valuable time and money.

Apply data insights to detect challenges, resolve inefficiencies, and elevate line performance.

COLLECT. IDENTIFY. VERIFY.

Pinpoint the root cause of damage on your line.

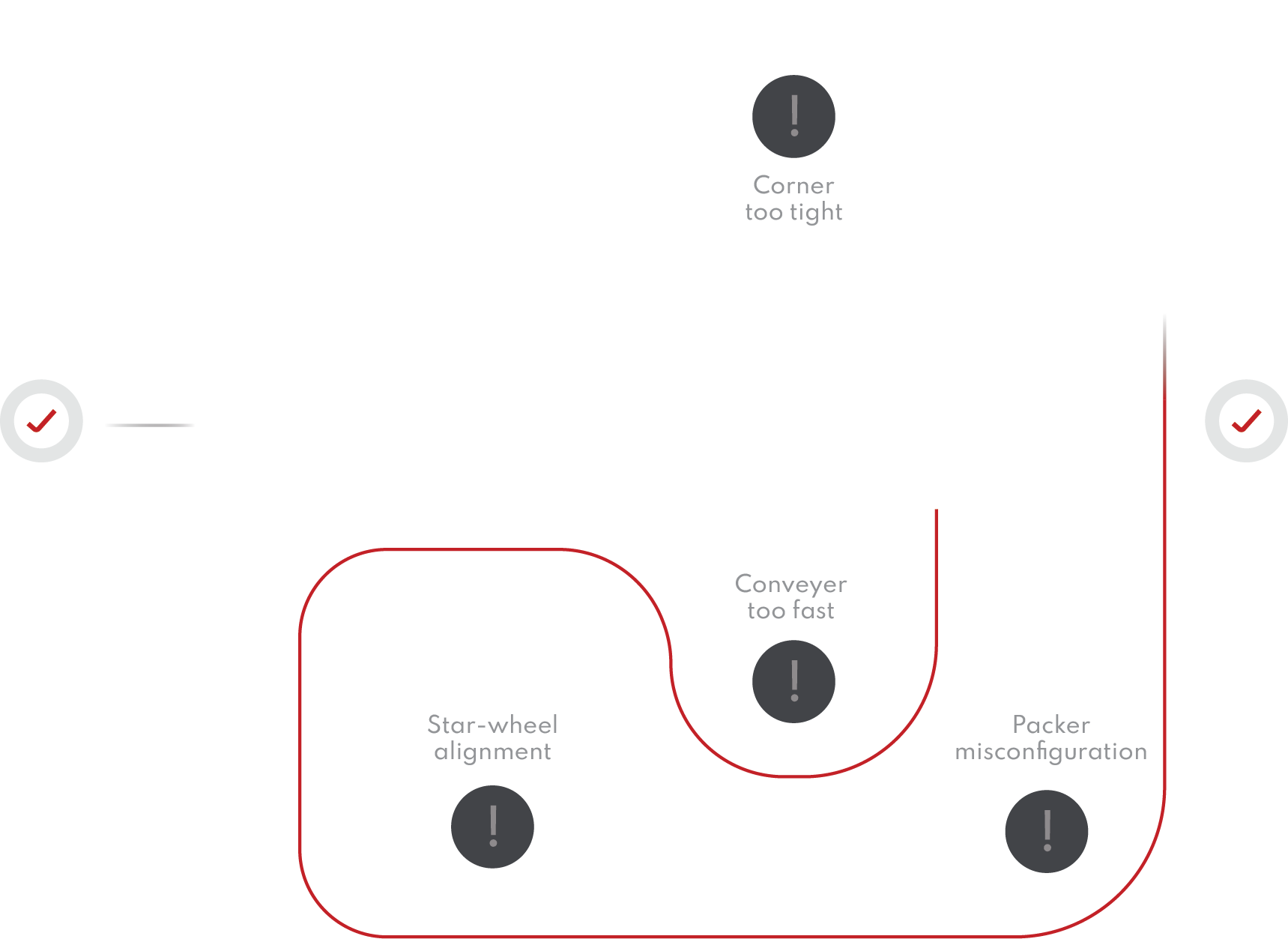

Our intuitive, easy-to-use container twins give you unprecedented visibility into your manufacturing line. By traveling through your conveying, filling, and packaging systems just like a real container, they precisely measure the magnitude and location of damaging forces in real time.

Whether it’s pressure, impact, vibration, or tilt, SmartSkin captures the data your containers can’t tell you — helping you pinpoint problem areas, reduce damage, and fine-tune your line for optimal performance and efficiency.

Solutions

Technology built for your environment.

Get a complete overview of your line’s container handling performance. Quickly and easily pinpoint problem areas and present information in a powerful and accessible way.

Whether you want to see your historical line performance for better managerial decisions, compare your line to a generated industry standard, diagnose issues within machines that are otherwise unknown, or improve your overall product quality, we can get you started.

Global Presence

FROM OUR CUSTOMERS

“The damage that was done from an incident last night, without SmartSkin, would’ve taken approx. 2 weeks to fix, and costed between $200,000 to $300,000, so the ROI is there, absolutely.”

“With SmartSkin we’re able to reduce glass defects, correct unexpected line behaviour across our fill-finish lines and enhance our team’s process knowledge and mastery.”

Schedule a Demo

Solve your container handling issues today.

Toll-Free: (855) 210-9006

Latest from SmartSkin

Data analytics in the pharmaceutical industry is evolving from being a compliance and reporting tool to playing [...]

PET (Polyethylene Terephthalate) dominates beverage packaging for good reason—it's clear, lightweight, durable, recyclable and therefore very economical. While [...]

In pharmaceutical fill-and-finish operations, maintaining high Overall Equipment Effectiveness (OEE) is essential not just for efficiency, but for [...]

SmartSkin Technologies is thrilled to welcome Austin Caudle as our new Vice President of Business Development – [...]

The first time I set foot on a high-speed beverage production line, the experience was overwhelming. Intense [...]

In high-speed beverage production, seamers are a crucial part of the manufacturing process and where can quality [...]